Oxford University physicists have developed a thin-film material that can be applied to the exterior of objects exposed to sunlight. The scientists believe this will offer a more compact alternative to traditional silicon-based solar panels.

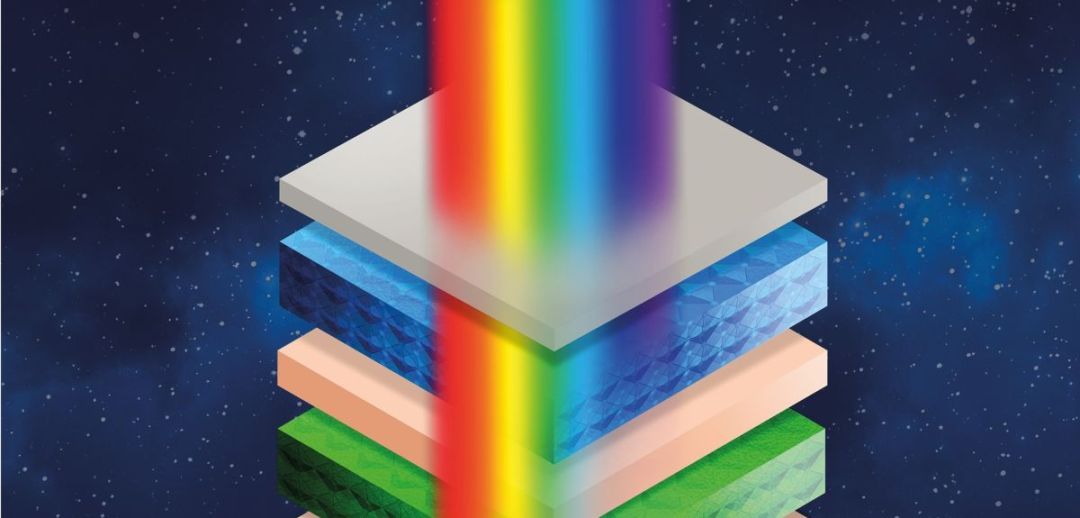

This flexible film, currently still in the research phase, is created by stacking multiple layers of light-absorbing perovskite, each just over one micron thick, into one solar cell.

According to Oxford University, the new material is 150 times thinner than a conventional silicon wafer and can deliver 5% more energy efficiency than standard single-layer silicon solar panels.

Dr. Shauifeng Hu, a postdoctoral fellow at Oxford’s physics department, states: “We believe that, over time, this approach could enable the photovoltaic devices to achieve far greater efficiencies, exceeding 45%.”

Meanwhile, Oxford University notes that the efficiency level of current solar modules is around 22%. Hu adds:

“During just five years experimenting with our stacking or multi-junction approach, we have raised power conversion efficiency from around 6% to over 27%, close to the limits of what single-layer photovoltaics can achieve today.”

The thin material and flexibility of the film allow it to be applied to nearly any surface, which could lower construction and installation expenses and boost the number of solar farms generating sustainable energy.

‘By using new materials which can be applied as a coating, we’ve shown we can replicate and out-perform silicon whilst also gaining flexibility,” comments Dr Junke Wang, Marie Skłodowska Curie Actions Postdoc Fellow at Oxford University Physics.

“This is important because it promises more solar power without the need for so many silicon-based panels or specially-built solar farms.”

Cost

The scientists hope the new material will reduce the cost of solar energy, making it the most sustainable and cost-effective of the current renewable options.

Oxford University says in their statement that, since 2010, the cost of solar has decreased by almost 90% on average, with discoveries such as this thin film offering further reductions.

Regarding the commercialisation of perovskite photovoltaics, co-founder and chief scientific officer of UK company Oxford PV, Professor Henry Snaith, explains in Oxford University’s statement the company’s decision to conduct large-scale manufacturing at its factory in Germany:

‘We originally looked at UK sites to start manufacturing but the government has yet to match the fiscal and commercial incentives on offer in other parts of Europe and the United States. Supplying these materials will be a fast-growth new industry in the global green economy and we have shown that the UK is innovating and leading the way scientifically.

“However, without new incentives and a better pathway to convert this innovation into manufacturing the UK will miss the opportunity to lead this new global industry.”

[Image credit: Oxford University]